Vacuum Sewage System

General Description

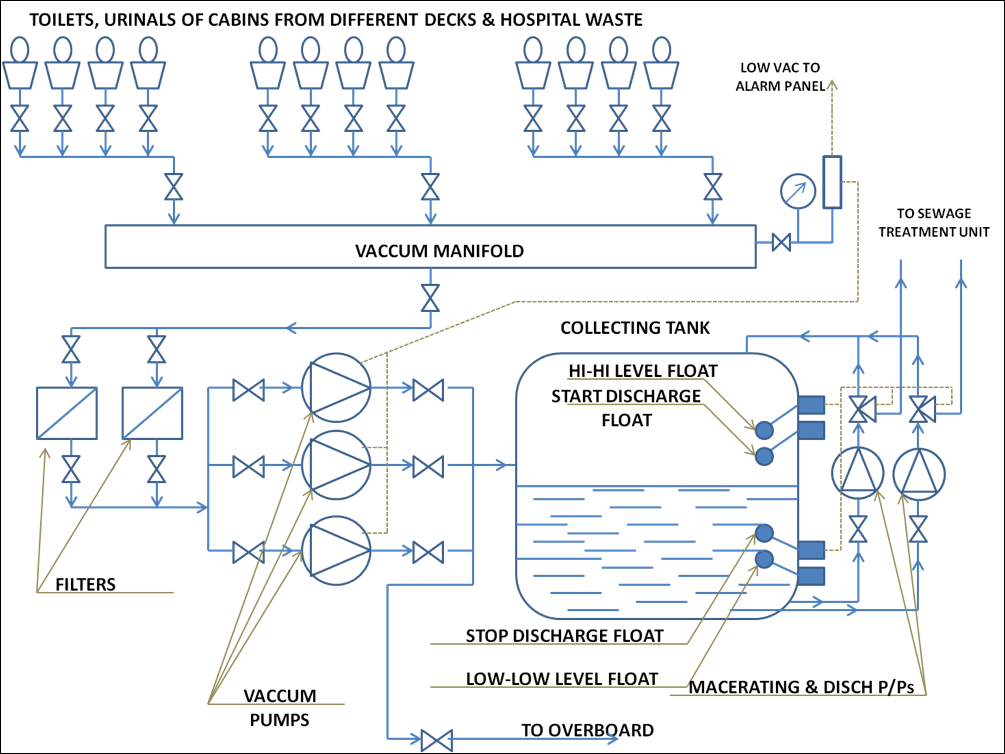

The system uses vacuum to transport sewage from toilets and urinals (Collected in a local tank behind the urinal and activated by a float as the level rises) to collecting units. There is a vacuum only ion the piping network and collecting units (Toilets, urinals etc.) remain under atmospheric pressure unless when the flush button is pushed; for a set value of time which is usually 7-15 seconds. Each toilet is connected to the vacuum piping. The connection is shut all times, except during the toilet flushing. When the toilet is flushed, its discharge valve opens the connection to the vacuum piping network for a pre-set seconds and the contents of the bowl will be evacuated into the sewer. The evacuated sewage, very less water sprayed by spraying nozzles, and few liters of air drawn during the flushing process, which pushes the sewage plug forward in the piping system as long as the discharge valve remains open.

Vacuum Pumps

The vacuum is created by specially designed jet pumps which are connected to a vacuum manifold runs continuously until the vacuum set point is reached on the vacuum manifold. There are number of such pumps (Depending upon the number of toilets installed in the ship) cut in / cut off sequentially by the vacuum reading on the main manifold. These vacuum creating pumps are cooled by water. Due to vacuum in the pumping space the water starts to boil and the pump parts become over heated to avoid this, a solenoid controlled valve activated by the temperature sensor fitted on the body opens up cooling water and closes when the temperature is under the limit. The cooling water is eventually mixed with the sewage and pumped to collecting tank. The sewage transported by the vacuum, prior entering the pumps, is passed through a coarse filter which collects all the papers and other foreign items like cigarette buds, papers etc. The sewage passes to the pumps and pumped into the collecting tank.

Collecting Tank

As the name implies collecting tanks are used to collect the contents that are transported by the vacuum pumps. Collecting tanks are usually of a higher capacity to meet the peak loading. CT is equipped with 2 or more pumps which continuously macerate (Break down) the raw sewage into fine particles and prepare for feeding into the treatment unit. Float switches are provided for an automatic operation of the collecting tanks; these switches perform the following tasks;

High Level

This is a dangerous condition which indicates the discharge 3-way valves or not opening to the treatment unit, pump faulty, too much of cooling water ingress i.e more than the discharge capacity of pump.

Start Discharge

This float activates the 3-way valve to discharge the contents to the treatment unit as the collecting tank is almost full and needs to be discharged into the treatment unit.

Stop Discharge

This float de-activates the 3 way valve and the discharge to the treatment unit stops. This is provided to maintain a level for the macerating pump to continue running and not run dry.

Low Level

Indicates low level on the collecting tank which may be due to faulty discharge valve which remain open and empty the tank and thus risking the macerating pumps which will run dry

ONE Main Advantage of the System

One of the main advantage of this system is that, very little flushing water is required and the volume of sewage dealt with can be much reduced with the downsizing of relevant equipment and cost saving. This has made them very popular for passenger vessels. Lloyd’s regulations state that the capacity of a sewage system for flushing water with conventional plant is 115 liters/ person/ day and 15 liters for vacuum systems.

One Main Disadvantage

The main disadvantage is blockage due to drying and crystallization of urea. Over a period of time this can be so severe as to completely close the pipes. Chemicals are on the market which can be added in very small doses which help remove and prevent these deposits but there success is not guaranteed.

why a holding tank may be required to be fitted to the system;

1) The holding tank, which is usually called as a collecting tank, as explained above is used to collect the sewage transported by the vacuum. In some designs the macerating pumps pump the content through an eductor which creates vacuum for the toilets instead of vacuum pumps.

2) The holding tank separates the negative and positive sides and also acts as an accumulator when the treatment units are full. Depending on the size of the vessel there may be 3 (Fwd section, midship, aft) up to

Problems resulting from the retention of untreated sewage in a holding tank.

1) The breakdown of raw sewage in water is effected by aerobic bacteria, as long as there is a relatively ample presence of oxygen to support the bacteria. In other words it’s effected by anaerobic bacteria if the oxygen has been depleted.

2) When the amount of sewage relative to water is small, dissolved oxygen in the water will assist a bio-chemical (aerobic) action which breaks down the sewage into simple, clean components and carbon dioxide. This type of action is produced in biological sewage treatment plant in which air (containing 21% oxygen) is bubbled through to sustain the aerobic bacteria.

3) In a holding tank if untreated sewage is stored then the bacteria turn into an aerobic due to poor oxygen supply which creates black sludge toxic and explosive gases which creates danger to the life of personnel working around, in some cases they could explode as well due to excessive accumulation of methane if a spark or heat source is introduced.