GUIDELINES FOR THE MAINTENANCE AND INSPECTIONS OF FIXED CARBON DIOXIDE FIRE-EXTINGUISHING SYSTEMS

GUIDELINES FOR THE MAINTENANCE AND INSPECTIONS OF FIXED CO2 CARBON DIOXIDE FIRE-EXTINGUISHING SYSTEMS

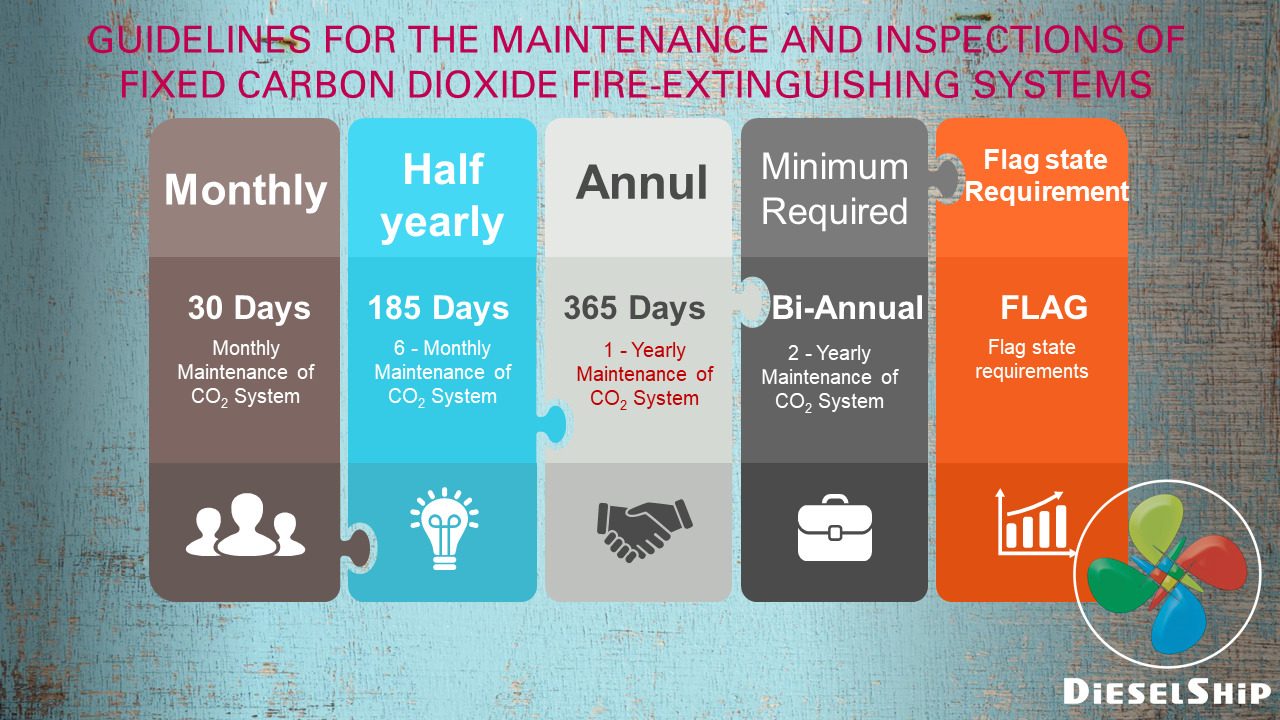

Monthly inspections

1. At least every 30 days a general visual inspection should be made of the overall system condition for obvious signs of damage, and should include verification that:

1.1 all stop valves are in the closed position;

1.2 all releasing controls are in the proper position and readily accessible for immediate use;

1.3 all discharge piping and pneumatic tubing is intact and has not been damaged;

1.4 all high pressure cylinders are in place and properly secured; and

1.5 the alarm devices are in place and do not appear damaged.

In addition, on low pressure systems the inspections should verify that:

1.6 the pressure gauge is reading in the normal range;

1.7 the liquid level indicator is reading within the proper level;

1.8 the manually operated storage tank main service valve is secured in the open position; and

1.9 the vapour supply line valve is secured in the open position.

2. Annual inspections

The following minimum level of maintenance and inspections should be carried out in accordance with the system manufacturer’s instructions and safety precautions:

2.1 the boundaries of the protected space should be visually inspected to confirm that

no modifications have been made to the enclosure that have created un-closeable openings that would render the system ineffective;

2.2 all storage containers should be visually inspected for any signs of damage, rust or

loose mounting hardware. Cylinders that are leaking, corroded, dented or bulging should be hydrostatically retested or replaced;

2.3 system piping should be visually inspected to check for damage, loose supports and corrosion. Nozzles should be inspected to ensure they have not been obstructed by the storage of spare parts or a new installation of structure or machinery;

2.4 the manifold should be inspected to verify that all flexible discharge hoses and fittings are properly tightened; and

2.5 all entrance doors to the protected space should close properly and should have warning signs, which indicate that the space is protected by a fixed carbon dioxide system and that personnel should evacuate immediately if the alarms sound. All remote releasing controls should be checked for clear operating instructions and indication as to the space served.

3. Other minimum recommended maintenance

3.1 At least biennially (intervals of 2 years ± 3 months) in passenger ships or at each intermediate, periodical or renewal survey in cargo ships, the following maintenance should be carried out.

Find recommended service charts attached here.

1. Example of service charts – for High pressure CO2 system

2. Example of service charts – for Low pressure CO2 system

The following maintenance should be carried out.

3.1 All high pressure cylinders and pilot cylinders should be weighed or have their contents verified by other reliable means to confirm that the available charge in each is above 90% of the nominal charge. Cylinders containing less than 90% of the nominal charge should be refilled.

> The liquid level of low pressure storage tanks should be checked to verify that the required amount of carbon dioxide to protect the largest hazard is available;

3.2 the hydrostatic test date of all storage containers should be checked. High pressure cylinders should be subjected to periodical tests at intervals not exceeding 10 years. At the 10-year inspection, at least 10% of the total number provided should be subjected to an internal inspection and hydrostatic test.

>> If one or more cylinders fail, a total of 50% of the onboard cylinders should be tested. If further cylinders fail, all cylinders should be tested. Flexible hoses should be replaced at the intervals recommended by the manufacturer and not exceeding every 10 years.

3.3 the discharge piping and nozzles should be tested to verify that they are not blocked. The test should be performed by isolating the discharge piping from the system and flowing dry air or nitrogen from test cylinders or suitable means through the piping.

4. Requirement of Flag state

At least biennially (intervals of 2 years ± 3 months) in passenger ships or at each renewal survey in cargo ships, the following maintenance should be carried out by service technicians/specialists trained to standards accepted by the Administration:

4.1 where possible, all activating heads should be removed from the cylinder valves and tested for correct functioning by applying full working pressure through the pilot lines.

4.2 In cases where this is not possible, pilot lines should be disconnected from the cylinder valves and blanked off or connected together and tested with full working pressure from the release station and checked for leakage.

In both cases this should be carried out from one or more release stations when

installed.

4.3 If manual pull cables operate the remote release controls, they should be checked to verify the cables and corner pulleys are in good condition and freely move and do not require an excessive amount of travel to activate the system;

4.4 all cable components should be cleaned and adjusted as necessary, and the cable

connectors should be properly tightened. If the remote release controls are operated by pneumatic pressure, the tubing should be checked for leakage, and the proper charge of the remote releasing station pilot gas cylinders should be verified. All controls and warning devices should function normally, and the time delay, if fitted should prevent the discharge of gas for the required time period;

4.3 after completion of the work, the system should be returned to service. All releasing controls should be verified in the proper position and connected to the correct control valves. All pressure switch interlocks should be reset and returned to service. All stop valves should be in the closed position.

Just want to clarify regarding safety pins on fixed co2 sytem. We have been inspected by the psc inspector and they insist that the safety pins should be inserted all the time for safety. Base on my experience safety pins are only inserted on the trigger valve during maintenace or transportaion of co2 cylinder or if i am not mistaken and in port. But during voyage all safety pins should be take out from the valve. Can someone give me a an actual fact or written copy stating that safety pins should or should not be inserted prior to emergency situation. Thanks

It’s clearly mentioned in manual that pins should be inserted only during maintenance and transport , while during normal voyage pin should be out at all times. It’s clearly mentioned in all manuals. Same question I asked to Flag state inspector he suggested me that just do what manual says.

Hello Clint, the PSC inspector is absolutely wrong, there are many safeties provided in the system to ensure the accidental release is not flooded into the protected space.

Apart from that, the SOLAS requirement is to release it from any dedicated remote location, and timing of the flooding and flooding the calculated volume of CO2 in 2 minutes is highly necessary to ensure the flooding operation is effective.

The pin is inserted only when any maintenance is underway where other safties that prevent accidental flooding such as the sectional valve, Master valve may have been removed or left open!

I dont think so it is written anywhere that the pins should be inserted or removed! but it is purely of common sense that if pins are inserted it is unsafe where as you will need someone to go and remove the pins.

I mainly worked in cruise ships, where 200 cylinders are present, who is going to sit there in the room during a fire and remove these pins???

Its all depends on the type of Co2 system.. Please refer shipboard manual.

services nneded

Hello clint here in my vessel where I onboard and PSC surprise inspection conducted notice this safety pin which was inserted and he speaks us it should be remove.