Ballast Water Treatment (BWT) System and different types

Ballast Water Treatment (BWT) System and different types

Discharge criteria

– Any type approved ballast water treatment system shall comply with the discharge criteria regulation D2 and they are;

Capacity discharge for organisms;

- Less than 10 organisms per m3, for organisms> 50 micrometers,

- Less than 10 organisms per ml, for organisms between 10 and 50 microns.

Capacity of indicator microbes; ( cfu – colony forming unit)

- Toxigenic vibrio cholera: 1 cfu per 100 ml

- Escherichia coli: 250 cfu per 100 ml

- Intestinal enterococci: 100 cfu per 100 ml

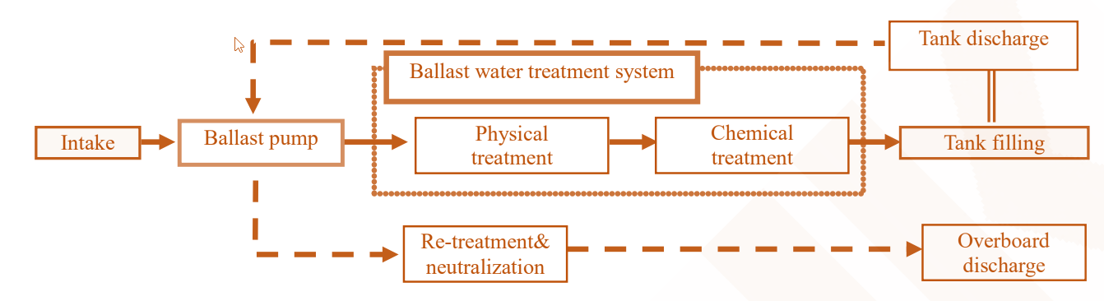

General structure of a Ballast Water Treatment (BWT) System

– The ballast water is generally passed through a filter for physical treatment to remove living organisms and dirt of size 50 microns and above. Some systems use cavitation devices as physical treatment.

– The ballast water is generally passed through a filter for physical treatment to remove living organisms and dirt of size 50 microns and above. Some systems use cavitation devices as physical treatment.

– Later, the ballast water is sterilized to kill microbes by chemical treatment using chemicals and the treated water is filled in ballast tanks. Methods include emitting ultra-violet rays in water, reducing the oxygen content in water, adding active substances such as ozone and using its sterilizing ability, sterilizing water by using chemicals etc.

– Subsequently, the water is discharged overboard, but for a system in which re-treatment or neutralization is necessary, the water is discharged overboard after such treatment has been performed.

Different types of ballast water treatment system

There are 4 different types of ballast water treatment system commonly used. They are;

- UV treatment method

-

Gas Treatment method

-

Electrolysis method

-

Magnetic Separation method.

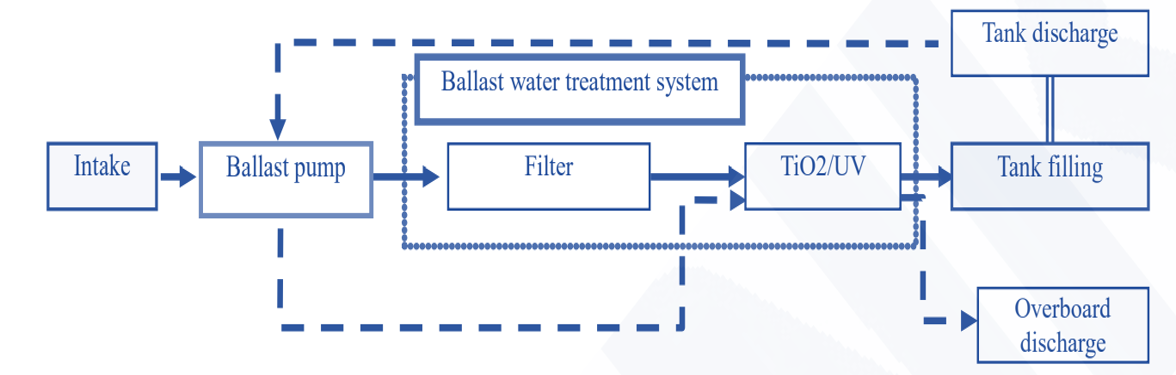

a) UV Treatment method

– Figure shows an overview of the UV treatment method. Large aquatic organisms are removed together with dirt in the first stage filter. Subsequently, light is emitted on titanium dioxide, and the radicals generated sterilize aquatic organisms and other fungi.

– Figure shows an overview of the UV treatment method. Large aquatic organisms are removed together with dirt in the first stage filter. Subsequently, light is emitted on titanium dioxide, and the radicals generated sterilize aquatic organisms and other fungi.

– An atom or a molecule with an unpaired electron is a radical. By radiating light of a specific wavelength, titanium dioxide generates active oxygen and hydroxyl radicals (OH radical), which has strong disinfection.

– In addition, some system uses ultraviolet rays to sterilize. Micro-organisms, fungi, etc. may regenerate in the tanks because this treatment system does not use chemicals. Therefore, ballast water needs to be treated by the BWT system again before it is discharged.

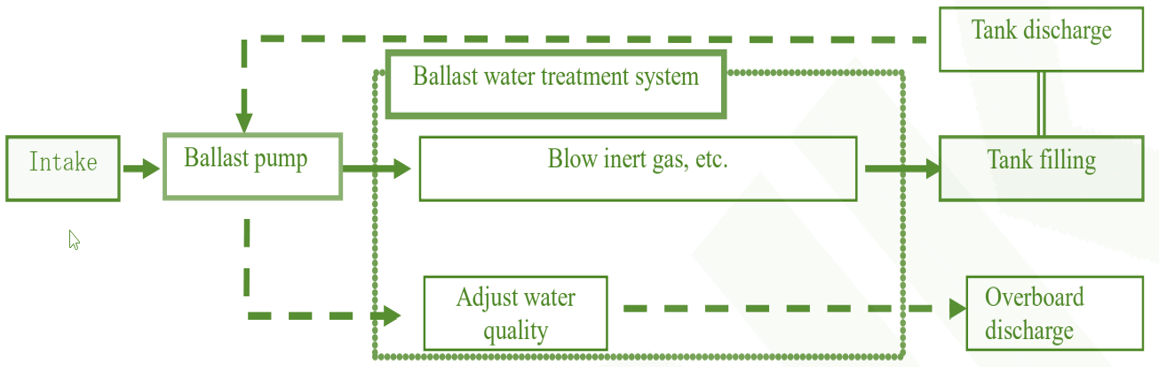

b) Gas Treatment method

– Figure shows an overview of the gas treatment method. When filling ballast water, Inert gas is blown into the ballast water using a Venturi tube, the oxygen concentration of water is reduced, and ballast water is sterilized.

– Figure shows an overview of the gas treatment method. When filling ballast water, Inert gas is blown into the ballast water using a Venturi tube, the oxygen concentration of water is reduced, and ballast water is sterilized.

– The oxygen concentration of inert gas is lower than 0.1%, and this is lower than inert gas used for oil tankers (lower than 5%). In addition, some system uses ozone which has strong disinfection. These treatment methods may need neutralization process or water quality adjustment during discharge of ballast water.

c) Electrolysis method

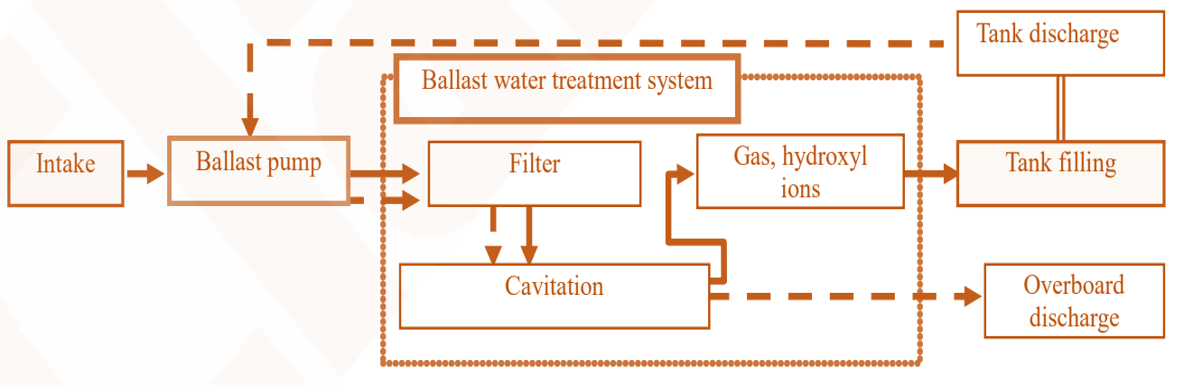

Figure shows an overview of the electrolysis treatment method with filtration & cavitation. The uptake ballast water is passed through filters and large aquatic organisms and dirt more than 50 microns are removed. – Cavitation damages the cell membranes of organisms, and nitrogen gas purified onboard and hydroxyl ions generated by electrolysis are added to sterilize and to kill aquatic organisms and fungi. – There are no active substances that are brought into the ship from outside the ship.

Figure shows an overview of the electrolysis treatment method with filtration & cavitation. The uptake ballast water is passed through filters and large aquatic organisms and dirt more than 50 microns are removed. – Cavitation damages the cell membranes of organisms, and nitrogen gas purified onboard and hydroxyl ions generated by electrolysis are added to sterilize and to kill aquatic organisms and fungi. – There are no active substances that are brought into the ship from outside the ship.

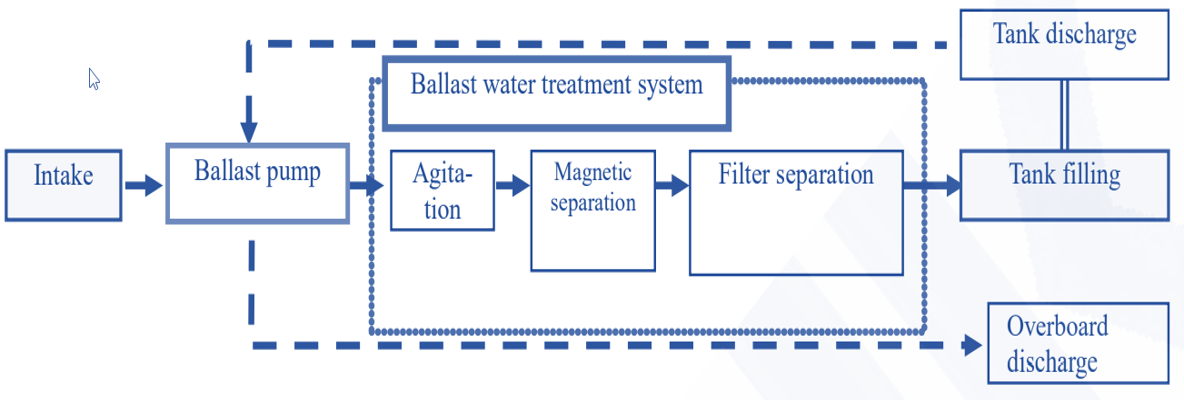

d) Magnetic Separation method.

– Figure shows an overview of the magnetic separation treatment method. This is a treatment system for aquatic organisms, micro-organisms, and microbes in which magnetic powder is fed to the ballast water during its filling, water is agitated and magnetic separation performed.

– No chemicals for sterilization are used. The aqueous ingredients in ballast water are also unchanged, and re-treatment of discharged water, neutralization, etc., are not necessary.